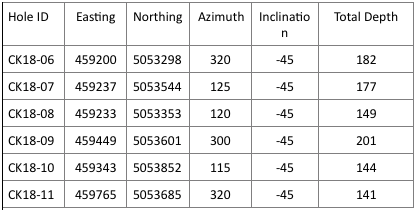

UTM Coordinates: NAD83, Zone 18N

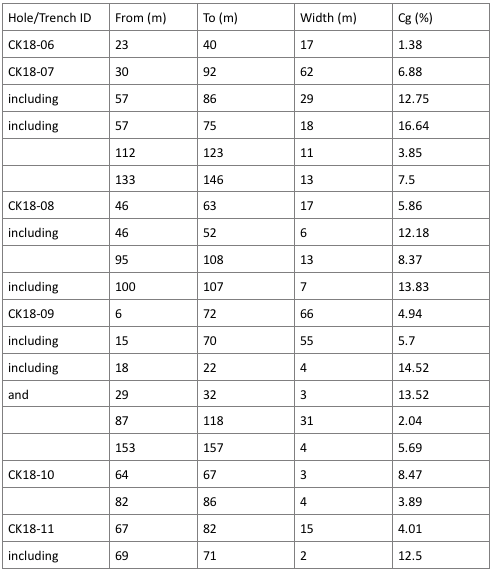

The drilling follows up on positive results of previous work including airborne electromagnetics, trenching and a first stage drill program undertaken during 2016 and 2017. Hole CK-18-06 was drilled to the northwest to test the thickest portion of the 1.54 kilometre long northeast-southwest trending electromagnetic (EM) conductor and intersected low grade graphite mineralization associated with carbonate horizons in quartzo-feldspatic gneiss. Hole CK 18-07 was drilled to the southeast through the conductor between trenches 5 and 6 from the 2017 program. The hole intersected three graphite zones between 30 and 146 metres, with the highest grades associated with marble zones within gneiss. Hole CK18-08 was collared approximately 50m north of hole CK18-06 and drilled to the southeast. It intersected two graphite zones from 46 to 63 metres and from 95 to 108 metres with higher grades again associated with marble horizons. Hole CK18-09 was drilled to the northwest across a narrowing of the EM anomaly and intersected three graphite zones between 6 metres and 157 metres. Graphite mineralization in the near surface zone is associated with intervals of marble within the gneiss. Holes CK18-10 and CK18-11 were drilled across conductors in the vicinity of trench 2 and trench 10, respectively. Both holes showed relatively narrow intervals of graphite associated with marble.

All samples were placed in a plastic sample bag along with a sample tag. Bags were sealed with a single use tie. Samples were securely stored prior to shipping to SGS in Lakefield Ontario. Samples were crushed, milled and roasted and treated by HCl leach prior to being assayed by the combustion infrared technique (LECO). The Company routinely submits standards, duplicates and blanks with sample batches to monitor the quality of the assays.

The technical content of this News Release was reviewed and approved by Roger Moss Ph.D., P.Geo, a qualified person as defined by National Instrument 43-101.